Nose-to-tail modification

Jonathan Falconer investigates whether modifying existing aircraft is a better option than purchasing brand new, bespoke platforms direct from the OEMs with all the modifications and configurations as a package

Special missions require special aircraft. At the least, firefighters need capacity to carry large payloads and airframes that are tough enough to handle suddenly dropping the suppressant/retardant; search and rescue (SAR) need winches and the ability to fly smoothly through hot and high altitudes or at turbulent low levels across the ocean; helicopter emergency medical services (HEMS) need space for reclining patients and special medical equipment; and police need searchlights and cameras.

What makes the modification of existing aircraft more favorable, or are operators better off purchasing brand new, bespoke craft direct from the original equipment manufacturers (OEMs) with all the modifications and configurations as a package?

NPAS – a balance between airframe and mission system

So, when is modification better than brand new? Captain Paul Watts is Head of Flight Operations for the UK’s National Police Air Service (NPAS) and has 23 years’ experience in police aviation. He is also part of the NPAS procurement team for the acquisition of new rotary aircraft. For Watts, modification versus new is a balance between airframe and mission system.

“NPAS operates the world leaders (in flying hours) of the EC135 and EC145 helicopters and are experiencing the effects of operating an aging fleet, with increased maintenance times and aircraft on ground (AOGs) leading to decreased availability for each airframe,” he said. “This is an inevitable consequence as aircraft become older, accumulating flying hours; however, this has not manifested itself as a linear increase in aircraft downtime.”

An aircraft of two parts

“There are really two parts to the police aircraft as a system,” Watts explained. “Firstly, there’s the basic aircraft, including airframe, engines, gearboxes and associated accessories as supplied by the OEM. This aircraft is then modified with the addition of a mission system and electro-optical system camera. To perform the police role, both parts must operate effectively. However, we have seen a difference in ability to maintain both parts of the system as they age.”

Maintenance providers and OEMs have highly developed systems to ensure that aircraft can be maintained and operated safely for many years

The NPAS rotary wing fleet was inherited from the UK’s 43 police forces when NPAS was formed as a national collaboration in 2012, which means the aircraft have a mix of cameras and mission systems. “Our EC135 ‘T’ fleet do have a common system comprised of an MX-15 camera and AIMS mission system, which is also used in the Vulcanair fixed-wing aircraft,” he revealed. “The remaining EC135 and EC145 aircraft have a mix of FLIR Star SAFIRE and WESCAM MX-15 systems.”

The basic aircraft experiences an increase in maintenance times and AOGs, although at a certain point these plateau and the aircraft can still be effectively maintained, albeit with more maintenance intervention.

Watts said: “Maintenance providers and OEMs have highly developed systems to ensure that aircraft can be maintained and operated safely for many years. The mission system is more bespoke and relies on components from a variety of manufacturers. As the aircraft ages, more of these components become obsolete and it can be difficult to source suitable alternatives, meaning that the availability of the mission system can become increasingly poor with time,” he disclosed.

Mid-life upgrades

This disparity between the serviceability of the aircraft and mission system means that it often makes both economic and operational sense to incorporate a mid-life upgrade of the mission system to make full use of the life of the aircraft.

It often makes both economic and operational sense to incorporate a mid-life upgrade of the mission system to make full use of the life of the aircraft

“This approach should provide better value than replacing the entire aircraft system at the point that the mission system becomes obsolete,” asserted Watts. “Of course, there will eventually be a point at which the serviceability of the aircraft and mission system reduces to the point that it cannot support demand and new aircraft will be required. Acquisition of new aircraft also gives an opportunity to take advantage of technological advances in both aircraft and mission equipment.”

Talon Helicopters – multiple configurations

Over in western Canada, Talon Helicopters is based in Richmond, British Columbia. It is Vancouver’s premier supplier of helicopter services and the region’s largest supplier of intermediate helicopters. Peter Murray is Talon’s President: “We are a locally owned and operated helicopter service. Keep in mind that our operations require our AS365 Dauphin to be ready to go in minutes in VIP, medevac (with a Transport Canada (TC)-approved litter kit), SAR, hoisting and wildfire suppression with a belly tank. The Dauphin fits that role extremely well for us – it’s the Swiss Army Knife of helicopters,” he commented.

For the VIP interior configuration, Talon designed its own black leather interior that is used for all of the mission profiles mentioned above. “Strip out mission gear and hoist,” proclaimed Murray, “and voilà! Ferrari-style fast car VIP interior.”

For SAR and hoisting, the hoist system is direct from the OEM, which makes better sense for Talon. “Supplemental type certificated (STC) after-market hoist approvals can cause issues with certification in Canada,” revealed Murray. “Talon TC approved all the harnesses and designed and approved specific mission gear for the AS365.”

For medevac, Talon has an aftermarket Air Ambulance Technology litter kit that it paid to have TC approval. “It installs in five minutes and is perfect for ad hoc medevac operations,” said Murray.

Modification versus brand new

Murray explained that, in certain circumstances, modification of existing airframes is better than buying brand new. “When the helicopter is used only occasionally for medevac, such as in our operations, it can only be done by modifying existing, proven airframes,” he said. “New aircraft from the OEMs come with higher cost and someone has to pay for that. Most customers are cost conscious and when the price is double when utilizing new aircraft, existing aircraft are more favorable.”

Nikolaos Mavrikis, Director of the Special Mission Aircraft Division at Rheinland Air Service (RAS) explained the procedure in four parts for getting an aircraft modified for a specific use: “Detailed scope definition with customer: the process begins with a phase of understanding and detailing the scope and intended use of the aircraft in cooperation with the customer. This involves in-depth discussions to capture precise operational requirements and mission-specific needs.

“Specification development: based on the detailed scope, RAS develops a precise specification that outlines the exact requirements and capabilities needed for the special mission. This specification serves as the blueprint for selecting and implementing the necessary modifications.

“System selection: with a clear specification in hand, RAS selects the required systems. This selection process leverages their existing relationships and arrangements with numerous high-performance equipment OEMs and dealerships. These partnerships ensure that the chosen systems meet the highest standards of quality, functionality, and integration capabilities.

There are manifold considerations to take into account when deciding to modify or upgrade an airframe

“Integration and interface management: ensuring seamless integration and compatibility between individual systems is crucial. RAS manages the interfaces between the systems to guarantee optimal performance and reliability.”

Mavrikis continued to to say that there are manifold considerations to take into account when deciding to modify or upgrade an airframe: “When modifying or upgrading a platform, its crucial to ensure that the identified platform and the requested systems align with the intended operation and flight envelope. The following factors must be considered to address potential limitations: weight, power consumption, space envelope, maintainability, flexibility when configuration changes are required, impact on the original airframe, etc.”

Aircraft availability

If you are looking for a higher aircraft availability rate, Murray argues convincingly for use of existing aircraft. “Just poke around the industry and you’ll find a shortage of parts for the newer aircraft due to the lack of used parts in the world market for these newer airframes,” he pointed out. “Very nice to have new, but if you can’t get a transmission for two years that doesn’t help your customers out very much.” He explained there are far more options out there for existing airframes that have been flying successfully for 30 or more years to keep aircraft available for flight operations.

Just poke around the industry and you’ll find a shortage of parts for the newer aircraft

Brand new bespoke

When asked if operators are better off purchasing brand new bespoke aircraft direct from the OEMs with all the modifications and configurations as a package, Murray had this to say: “Only if your company has a dedicated government contract of 10 years or more. And a government with deep pockets to pay the much higher capital costs that come with new aircraft acquisition. Those contracts are out there, and in those cases a complete OEM medevac package may fit the bill.”

Mavrikis said that there are numerous benefits for deciding to follow the modification or upgrade route, highlighting the specificity of an individual organizations needs rather than following a cookie cutter generic approach: “By upgrading your existing platform, you increase its value, avoiding the need to sell it for a low price and purchase an expensive new one. If you choose to sell the upgraded platform, you can often achieve higher profit margins. Upgrades can eliminate the high costs associated with system obsolescence and major repairs; and unlike ready-made or semi-finished platforms, upgrades allow you to customize your system fully to meet your specific needs.”

July 2024

Issue

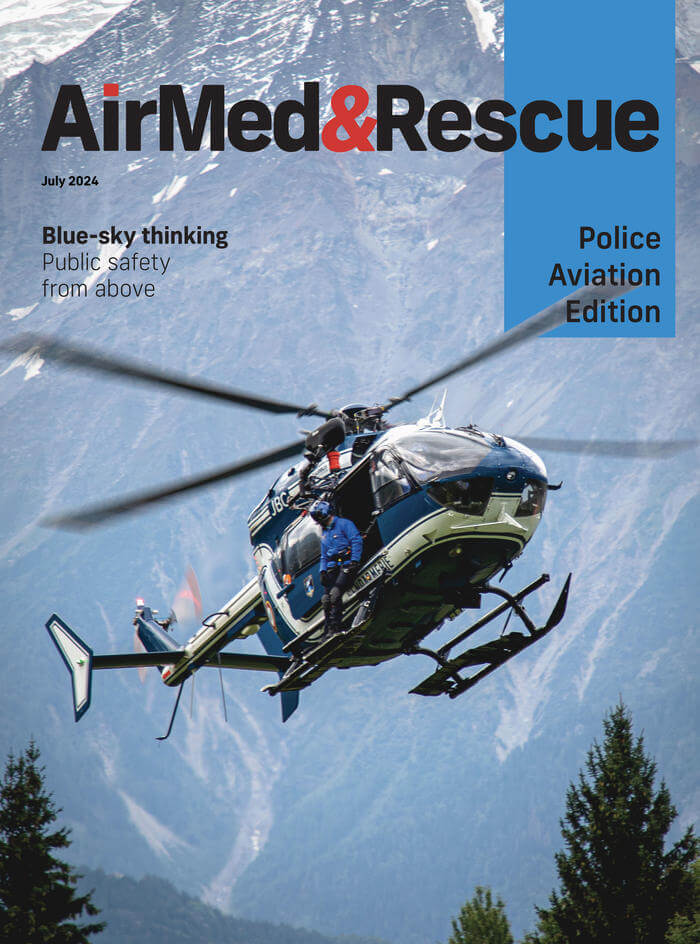

In our special police aviation edition in July, discover the considerations for urban public safety; read about the way drones are being used by the police; and discover how law enforcement agencies work with other agencies on complex operations; and find other features on treatment for major bleeding injuries; why health and usage monitoring systems are finding growth in the air medical sector; and the modification of aircraft for special missions; plus more of our regular content.

Jonathan Falconer

With many years as a publishing and editing professional under his belt, former Senior Editor with AirMed&Rescue, Jonathan continues as a freelance contributor. He was previously the Senior Commissioning Editor, Aviation & Military Titles, for Haynes Publishing. A keen aviation and military enthusiast, he brings a wealth of knowledge to the table.