HUMS AND MRO capabilities for airborne special missions operators

Health and usage monitoring systems (HUMS), engine management systems, and prognostic health management systems are developing critical mass in the air medical and rescue helicopter sectors

The role of HUMS is to help in proactive identification of any exceedances, triggering a need for taking a corrective action, according to Saravanan Rajarajan, Director of Aviation Solution Consulting at Ramco Systems, “This ultimately benefits the operator with increased aircraft/fleet reliability, more cost-effective parts management and streamlined shops visits, in addition to enhancing safety.”

Indeed, not knowing when the next out-of-service event is coming is a crucial point for operators, according to Todd Powers, Vice President of Sales at GPMS International. “Right now, they must react to unscheduled maintenance events after they happen as they do not have insight into the health of the most critical components on their aircraft,” he says.

Josh Kethan, Customer Success Manager at GPMS International, points out that helicopter air ambulance (HAA) and helicopter emergency medical services (HEMS) operators have strict requirements as to aircraft availability as the survival of a patient or an organ can be impacted by how quickly they are transported to a facility. “If an aircraft has a chip light in flight, the pilot now needs to land quickly to ensure the health of everyone on board, but in HAA/HEMS operations, this also puts further risk on the patient,” he says. “The benefit of prognostic HUMS and engine management systems is the ability to detect small issues and prevent them from becoming much larger issues, increasing the confidence in the aircraft and flight readiness.”

Newer systems have the ability to collect and analyse information from sensors strategically placed in critical systems of the aircraft, observes Tim Alden, Strategic Partnerships Director at Rusada. “But unlike old trend monitoring techniques that required PCMCIA downloads sent for analysis by the original equipment manufacturer (OEM), modern solutions are able to transmit information live, or near live, direct to operators. They in turn are armed with solutions that not only read the data but also make extrapolations and predictions of failure points,” he says. “As such, we move from a condition of waiting for a return on analysis, to a condition of day-by-day or mission-by-mission monitoring. Knowing which system is behaving outside of the desired operating range allows one to make much more informed decisions when planning maintenance.”

Data and insight into engines and vital components are provided by next-generation HUMS technology without invasive inspections, observes Kethan. “This gives HAA/HEMS operators performance data and near real-time insight to improve operational safety and efficiency and maximize aircraft availability.”

With prognostic HUMS, the operators are now able to be proactive and not only plan scheduled maintenance but also plan when unscheduled maintenance will likely need to occur through remaining useful life (RUL) capabilities, observes Powers. “With Foresight, aircraft data is automatically and wirelessly uploaded when the aircraft lands. Any alerts or warnings are automatically sent by SMS/email to the maintenance team, who can view a detailed report on not only that aircraft, but their entire fleet from any web-browser enabled device," he says. “The added benefit to being proactive and automated is that this greatly reduces the workload of pilots, and they are able to focus on the importance of the flight.”

New systems provide air medical operators with the information they need to become more efficient and sustainable, according to Powers. “The sophisticated analysis and forecasting provided by advanced HUMS like Foresight can fundamentally shift their approach to maintenance and management practices to become more proactive and less reactive," he says. “This shift to become more efficient is already occurring in other industries as they better utilize data, technology, and software to integrate business, management, and operational processes. Overall, the rotorcraft industry and maintenance organizations need to embrace this digital transformation more fully, though we are beginning to see it take shape.”

data on non-routine unscheduled removals, and no fault found events from the MRO system, along with HUMS data processed with the right software tools, will be the key for high accuracy of prediction

The periodic download of HUMS data along with maintenance-related data on the components/aircraft recorded in their MRO platforms provides vital intelligence on the heath of the components, according to Saravanan. “For example, data on non-routine unscheduled removals, and no fault found events from the MRO system, along with HUMS data processed with the right software tools, will be the key for high accuracy of prediction,” he says. “Data on the specific tail number can be compared with the rest of the fleet from the fleet maintenance reliability improvement.”

From a maintenance and airworthiness perspective, Rusada believes there is significant benefit in coupling the recorded data from flights or missions to the physical configuration of the aircraft. “The monitoring applications monitor systems or assemblies, whereas the maintenance systems hold the record of the components within the systems,” says Alden.

It is important to be able to look at the whole picture, according to Alden. “If a system is heading towards a limit of unacceptable performance, what events happened to the components associated with that system prior to the event? Has there been a change of a component in the system? Has the system been inspected recently as part of routine maintenance? Has the operating environment changed?” he says. “All that data is captured in a maintenance information system on a daily basis. Generating comparative reporting, or – better – still an alerting dashboard that complements the monitoring system, could allow the operator to make even better-informed decisions, not only about the aircraft experiencing the irregular event, but the rest of the fleet too.”

According to Powers, operators are also looking for solutions to integrate their existing software for activities such as inventory, maintenance planning and flight operations. “This is where advanced, cloud-based HUMS can shine with capabilities to quickly execute these integrations and further optimize operations. With prognostic HUMS and integrations, maintenance can be better predicted and scheduled, allowing for better planning and communication not only throughout the company but with customers, supply chains, and OEMs,” he says.

Kethan observes that for many operators it is difficult to react, not knowing when unscheduled maintenance is going to happen. “They have not thought about how they could have prevented it in the first place. One of the most overlooked benefits of our next-gen HUMS solutions is time," he says. “With Foresight, operators can move from reacting to unscheduled events to proactively planning based on their fleet schedule.”

Some challenges arise with data security for federal and military operators and some data privacy concerns for covered workforces, observes Kethan. “Anonymisation can be the solution. Our teams regularly work with our customers to customize data access based on the needs of their program” he says. “The age of aircraft is not an issue for us. In fact, our system is regularly retrofitted on legacy aircraft as they receive significant benefits from improved spares planning as finding these parts may be more difficult for them.”

According to Saravanan, one of the main hurdles faced by aircraft operators is currently the lack of standardisation on the data exchanges between the various HUMS and MRO systems.

challenges arise with data security for federal and military operators and some data privacy concerns for covered workforces

For operators and maintainers, the main obstacle is certification of the devices and the acceptance of the need in the market, according to Rusada. “There is a notion in the world that information is so plentiful and data devices so ubiquitous that the cost of such systems should be the same as a streaming service subscription, or the price of an app. It is therefore difficult for maintenance teams to justify investment in what appears to be just another set of fancy graphs,” says Alden. “But for those companies that are fully understanding the cost of downtime, misdiagnosed defects, and unnecessary part purchases, the prevention of those problems and associated costs fully justifies the cost of integrated data and analysis. Such data can also provide a greater level of confidence to crew both in the air and on the ground and facilitate decisionmaking.”

Regarding the new systems, the objective of MROs is to provide the foundational block to support predictive maintenance capabilities, points out Saravanan. “With the recent advancement in data processing power and the ability to store terabytes of data, the key challenge will be on agility to connect to the external ecosystems and leverage the data along with inhouse data for prediction”, he says. “For example, while predicting item removal through predictive maintenance, it is equally important to predict the replacement options available to keep the aircraft uptime as well as the other parts which might also be required during replacement.”

According to Kethan, several MRO providers may only see a customer’s aircraft during inspections and annuals. “This is like the case of going to the doctor only for one’s annual physical check. However, most times we do not get sick only once a year, and for some serious illnesses, the longer it takes to identify and begin treatment, the worse it gets, and the impacts are more severe,” he says. “With cloud-based HUMS, customers can choose to provide their MRO with access and visibility to the health and the operational history of their aircraft and make sure they receive SMS/email alerts for any issues.”

In this way, the operators' engineers and maintenance crews can watch the daily health of the aircraft and know ahead of time not only what scheduled maintenance is going to be needed, but also what unscheduled maintenance needs to occur and when based on trending components, affirms Kethan. “This provides the MRO with improved inventory planning and personnel scheduling to get the aircraft back up in the air faster, but more importantly, it keeps its customers flying safely,” he says.

According to Powers, for HAA and HEMS aircraft and operations, important thing is making sure that aircraft are available to answer the call and ensuring the safety and comfort of patients and crew. “Next-gen HUMS significantly improves operational safety and efficiency and is now lightweight, accurate, and most importantly affordable enough to become part of the operational standard in HAA/HEMS organizations,” he says. “More importantly, cloud-based solutions are designed to evolve and adapt and interface with other new technology and software. We consider this futureproofing the operators’ fleets.”

The newer systems are similar to how smartphones connected life to technology and became an integral part of it, observes Powers. “We have apps that interact and can share information, creating a knowledge network with tremendous potential. This is the direction I would like to see the HAA/HEMS industry continue towards: a connected fleet with integrated operations that will improve the safety and sustainability of our operations.”

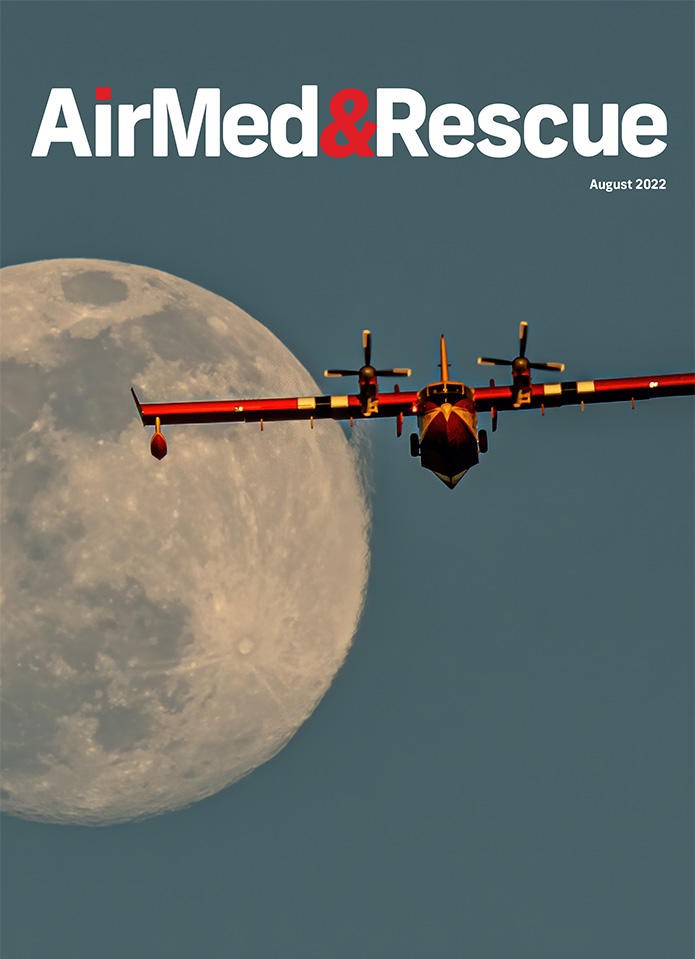

August 2022

Issue

In our August issue of AirMed&Rescue we look at survival, sustainability, and performance; both in the air and on the ground.

Mario Pierobon

Mario Pierobon is a safety management consultant and content producer. He writes extensively about aviation safety and has in-depth knowledge of the European aviation safety regulations on both fixed and rotary wing operations. His rotary wing expertise is concerned primarily with specialised operations and the operations requiring specific approval, such as HEMS, hoist operations and performance-based navigation.