Going big: Large and very large aerial firefighting airtankers

Operators of large and very large airtankers talk to Barry D Smith to discover the benefits and considerations of managing a fleet of these specialized fixed-wing aircraft

While the first fixed-wing airtankers were small, single-engine aircraft, larger versions were soon developed in the early 1960s. These consisted mostly of multiple models of ex-military bombers and cargo aircraft. Faced with years of hard use in low-level turbulence and high-G maneuvers, metal fatigue problems began to arise. In 2002, two fatal accidents occurred where the wings failed during a drop mission. The US Forest Service (USFS) suspended the contracts for certain airtanker types and created a panel to look at the airworthiness of the large airtankers (LAT) as a whole. In 2004, the contracts for all LATs were cancelled due to safety concerns.

A high conversion rate

When the USFS created contracts for new tankers, many safety and performance criteria were explicitly spelled out. Other countries have followed suit to ensure the highest level of safety for the high-risk task of aerial firefighting. A number of different airframes have been converted to airtankers over the past 20 years. They all share common factors, such as good low-speed handling, rugged construction and reliability.

The Conair Group of Abbotsford, British Columbia, has been operating airtankers for more than 50 years. They have converted over 15 aircraft types, with more than 175 produced. Their current large airtankers are the Avro RJ85 and Bombardier Dash 8-400. Its US subsidiary, Aero-Flite Inc. of Spokane, Washington, also operates the RJ85.

“A large airtanker conversion is an extraordinarily long process, requiring a significant investment,” explained Larry Pahl, Director of Airworthiness Engineering at Conair. “Nearly 15 years ago, when we started converting the RJ85, we were impressed with the aircraft’s speed and ability to carry 3,000 gallons (11,350 liters) of retardant, while still maneuvering well in challenging conditions at low speeds and low elevations on 3.5-hour missions before having to refuel.”

A large airtanker conversion is an extraordinarily long process, requiring a significant investment

“The newest airtanker we are converting today is the turboprop Dash 8-400AT,” stated Jeff Berry, Director of Business Development at Conair. “We evaluated 29 large aircraft before selecting the Dash 8-400. We selected it as it could land at shorter runways than other large airtankers, locating it closer to where fires occur. It can carry 2,600 gallons (10,000 liters) of retardant, and flies as fast as a jet to fires. In addition, it is fully supported by the original equipment manufacturer De Havilland Canada, with an ample supply of parts available for years to come, making it less costly to maintain. Plus, it burns far less fuel than other large airtankers, so its operationally less expensive.”

Damage Rate Factor

Conair made the decision to install external water/retardant tanks instead of internal ones. The external tanks preserve the integrity of the airframe, allowing the aircraft to remain pressurized, reducing pilot fatigue. The external configuration also enables the multi-role variant of the Dash 8-400 airtanker to have its tank removed during non-wildfire emergency response missions, transporting cargo and passengers in the interior.

When the USFS created contracts for new tankers, many safety and performance criteria were explicitly spelled out

“To account for the fatigue impact of the firefighting role on the structural integrity, we employ a Damage Rate Factor for firefighting where each mission on the Dash 8-400 airtanker is equivalent to a multiple of commercial cycles on the airliner version of the airframe,” said Brent Misura, Director of Engineering and Customer Service with Conair. “Prior to selecting the Dash, we consulted with all airframe manufacturers and by far the Dash 8-400 airframe would perform significantly better over the long term in the aerial firefighting role, with some manufacturers projecting the Damage Rate Factor to be 20 cycles or more for every aerial firefighting cycle.”

Each Conair airtanker undergoes heavy maintenance between fire seasons, with extensive annual testing and inspection processes to identify metal fatigue, including Non-Destructive testing – such as X-ray, eddy current, eddy current array, and ultrasonic methods, to locate sub-surface cracks without harming the integrity of the aircraft structure.

“One of the most notable tools protecting both the safety of our crews and integrity of the airframe, is our Transport Canada certified Flight Envelope Awareness System, developed by our in-house engineers,” explained Brent. “It is installed in the flight deck and designed to provide pilots with enhanced safety awareness information, such as slow speed awareness and angle of attack detail. This technology produces safer operations, as it prevents flight envelopes exceedances and excessive G loads, as opposed to measuring them after the damage has occurred. The system is in the pilot’s field of view, enabling them to stay in the safe zone and minimize exposure of the aircraft to high-risk excursions outside of the flight envelope.”

Conair has supported the French government for decades by providing airtankers for their fleet; first the S-2 Fire Cat and now with the Dash 8-400MRE multi-role airtanker, offering passenger, cargo and medevac support in addition to airtanker capability. The 8th Dash 8-400MRE airtanker, converted in-house by Conair, will be delivered to France later this year.

Speed is of the essence

Neptune Aviation of Missoula, Montana, is another long-time provider of airtankers.

“When we began looking for an airframe to replace our piston-engine P2V tankers, we wanted an aircraft with good maneuverability and an excellent safety record, that could be quickly loaded and launched within about ten minutes after it landed at a tanker base,” explained Kevin Condit, Neptune Marketing Manager. “The (BAe)-146 checked all of the boxes for us. With a decade of experience with them now, it has been a great platform. British Aerospace was, and still is, a great partner with Neptune. We worked with them to test its maneuverability and its low and slow handling characteristics. It has excellent short field abilities and can work out of any retardant base in the US.”

Neptune has a nondestructive test lab at their headquarters, staffed with technicians that can assess any of the airframe or flight control components to check for fatigue cracks and excessive wear. They worked with the US Federal Aviation Administration (FAA) on modifying the aircraft’s maintenance schedule to compensate for the heavier use and strain of life as an airtanker.

“We have nine BAe-146 tankers, each with a 3,000 gallon (11,350 liter) internal retardant tank,” stated Condit. “We did this to keep the cabin pressurized and maintain the same center of gravity and mass that the aircraft had when it was used as a passenger aircraft. Our proprietary internal tank also allows a constant steady control of the drop pattern using computer-controlled valves, no matter what the attitude or g-force on the aircraft. We call it the Active Response Tank.”

A surfeit of options

Another operator of former passenger jets as airtankers is Erickson Aero Tankers of Madras, Oregon. They have converted seven McDonnell Douglas MD-87s with 3,000 gallon (11,350 liter) retardant tanks. They are capable of operating out of airports with 5,000 foot (1,500 meter) runways with a full load. They also offer a cruise speed of 450 knots (830km/h) for fast turnarounds.

One of the newest operators of LATs is Coulson Aviation of Port Alberni, British Columbia, Canada. They currently build and use Lockheed C-130H Hercules and Boeing 737 airtankers. Both use Coulson’s proprietary 4,000 gallon (15,000 liter) tank. The tank for the C-130s is a roll-on, roll-off model, which can be changed out in about an hour. Coulson purchased five C-130s from the Royal Norwegian Air Force. Coulson also bought six Boeing 737-300s from Southwest Airlines. Called the Fireliner, it can carry 72 passengers with the tank installed. It has proven very maneuverable on fires and can cruise at 450 knots (830km/h). Coulson has had contracts for both types in Australia, Argentina and Chile this year. Coulson has also sold Fireliners to government agencies in Australia and Argentina.

The only operator of very large airtankers (VLAT) is 10 Tanker of Albuquerque, New Mexico. They use four McDonnell Douglas DC-10-30s as tankers. When the DC-10 was beginning to be phased out of air cargo work, the founders of 10 Tanker thought it would make a good airtanker and could be purchased at a reasonable price. Its engines are very powerful and, although large, it is highly a maneuverable aircraft. In addition, the tall landing gear would allow an external tank to be mounted to the belly. It uses a gravity flow tank system, which 10 Tanker believes produces a better drop pattern than a pressurized system.

“In the beginning, there was resistance from firefighting agencies to such a large aircraft being used as an airtanker,” commented RK Smithley, a DC-10 instructor pilot for 10 Tanker. “There were questions about maneuverability in steep terrain, how long it would take to reload and return to a fire, as well as the infrastructure needed to support it – such as longer runways and the physical size of the tanker base not being able to accommodate its wingspan.

DC-10 is now very popular and in demand during the US fire season

“There was also concern of the dollar cost of operating the DC-10,” Smithley continued. “However, once it was used on fires, the incident commanders saw its value and the DC-10 is now very popular and in demand during the US fire season. And since it carries 9,400 gallons (35,500 liters), the cost per gallon dropped is very competitive with other airtankers. While there are fewer bases it can operate from, it can cruise at 380mph (610km/h), which helps reduce round-trip times. It is not unusual for us to work on one fire, then be sent a thousand miles (1,600km) to another one at the end of the day. It flies at 40 per cent of max gross weight, which gives it a good thrust-to-weight ratio during missions. 10 Tanker dropped 12 million gallons of retardant with four aircraft in the 2021 fire season.”

10 Tanker uses Operational Limit Monitors that record stress at multiple points to pick up overloads and get a picture of the day-to-day stresses placed on the airframe during tanker missions. If anything occurs, the airframe, flight controls and engines can be checked for damage. This information can also be used for establishing time frames to check for fatigue during heavy maintenance in the off-season. While the pilots may fly seasonally, the maintenance crews work year-round.

Bigger is better

With many areas of the world experiencing extreme fire seasons, more countries are seeing the value of LATs and VLATs. South America has seen record-breaking wildland fire loss and is using these large tankers in increasing numbers. Currently, Coulson, Erickson Aero Tanker, and 10 Tanker all have aircraft operating in Chile. While there are many tools in the aerial firefighting toolbox, these large tankers are, and will continue to be, an important option for firefighting agencies.

May 2023

Issue

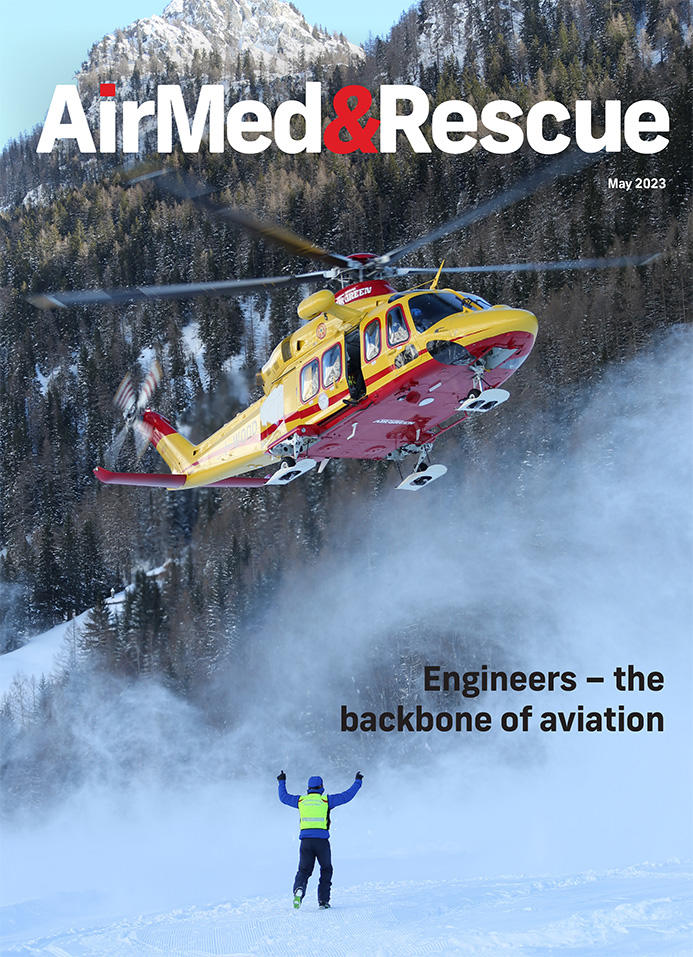

We speak to engineers about their work; we find out about the demands for transporting neonates; we explore when VLATs are the superior choice for firefighting; we look at the tools and training to ensure positive outcomes in the event of a power failure; plus all of our regular content.

Barry Smith

Barry Smith has been an aviation and emergency services writer/photographer for over thirty years. He has published over 250 magazine articles and six books. He has also worked in emergency services as a paramedic, volunteer firefighter, and member of search and rescue teams for over 40 years.