US Air Force new HH-60W combat rescue helicopter put through extreme weather tests

An HH-60W Jolly Green II, the Air Force's new combat search and rescue helicopter, completed a month-long trial of extreme weather conditions inside the McKinley Climatic Lab

The Sikorsky test aircraft endured real temperatures ranging from 120 degrees to minus 60 degrees Fahrenheit as well as 45-mph winds coupled with heavy rainfall. All of those scenarios were created within the lab’s 55,000-square-foot test chamber. The goal of these punishing tests was to prove the new aircraft’s sustainability in any operational environment.

“Operating the HH-60W in the extreme conditions was a truly unique experience as a pilot and a tester,” said Lt Col Ryan Coates, an 88th Test and Evaluation Squadron pilot, who performed most of the testing. “Checking system performance under the stress of heat, cold, heavy wind and rain will give us real-world data regarding the helicopter’s capability to perform the rescue mission worldwide in various environments, which is exactly what the operator needs to make solid employment decisions.”

Test, check, test again

Once the lab technicians created the extreme environments, aircrew would enter the aircraft and perform various test procedures. The crew would execute their preflight checklists and perform tasks to see if the extreme conditions affected any of the avionics, electronics, engine and other systems.

The aircrew performing the procedures were also test subjects themselves. Their own reactions and movements were evaluated in the harsh environment. For example, the cold-weather gear worn by the aircrew is much bulkier than a standard flight suit. One of the evaluations was to ensure the pilots could easily reach all of the aircraft controls in the thicker cold-weather gear.

A significant amount of the test schedule was dedicated to preparing the chamber for the extreme conditions. McKinley’s lab professionals create, break-down, and recreate again for each new test environment. Technicians worked continuously to go from a superheated 100-degree desert condition to a below freezing icebox in only three days.

“McKinley Climatic Laboratory maintains quickness and technical proficiency by retaining our own staff of highly experienced welders, machinists, electricians, instrumentation experts, test assembly personnel and refrigeration operators,” said William Higdon, the lab’s technical advisor. “Our main mission is to support the warfighter and to ensure any environment they encounter in the field; that their equipment has already been proven in those extremes.”

Ventilation challenges

The Jolly Green II created some unique challenges for McKinley Lab personnel. The lab technicians created a system specifically for the HH-60W to remove the aircraft’s exhaust. Thorough exhaust removal is a critical part of maintaining the controlled temperature conditions needed for chamber testing, according to lab technicians working on the test.

The design of the ventilation system meant the aircraft’s blades were removed for the duration of the testing. The lab’s in-house fabrication shop also specially designed brackets for the aircraft’s weapons among other items.

“Successful completion of this test is absolutely shared with the Sikorsky and McKinley teams,” said Ben Walker, the lead 413th Flight Test Squadron test engineer for the effort and Air Force PALACE Acquire journeyman. “Everyone worked together extremely well and we completed on time and on budget. I am very thankful for this opportunity to perform exciting engineering work, while also supporting the warfighter.”

After testing in the climatic lab, the HH-60W returned to Sikorsky’s test facility in West Palm Beach for further evaluation. The HH-60W developmental test program is a joint effort between Sikorsky, the 413th FLTS, and the 88th TES and Air Force Operational Test and Evaluation Center. Test aircraft are primarily split between Duke Field and Sikorsky’s West Palm Beach facility.

“Testing on the combat rescue helicopter continued amidst the chaos of Covid-19,” said Lt Col Wayne Dirkes, the 413th FLTS operations officer. “While the situation could change at any moment, we have not lost any test schedule thus far. That is a testament to the entire team’s attitude and willingness to work through challenges.”

June 2021

Issue

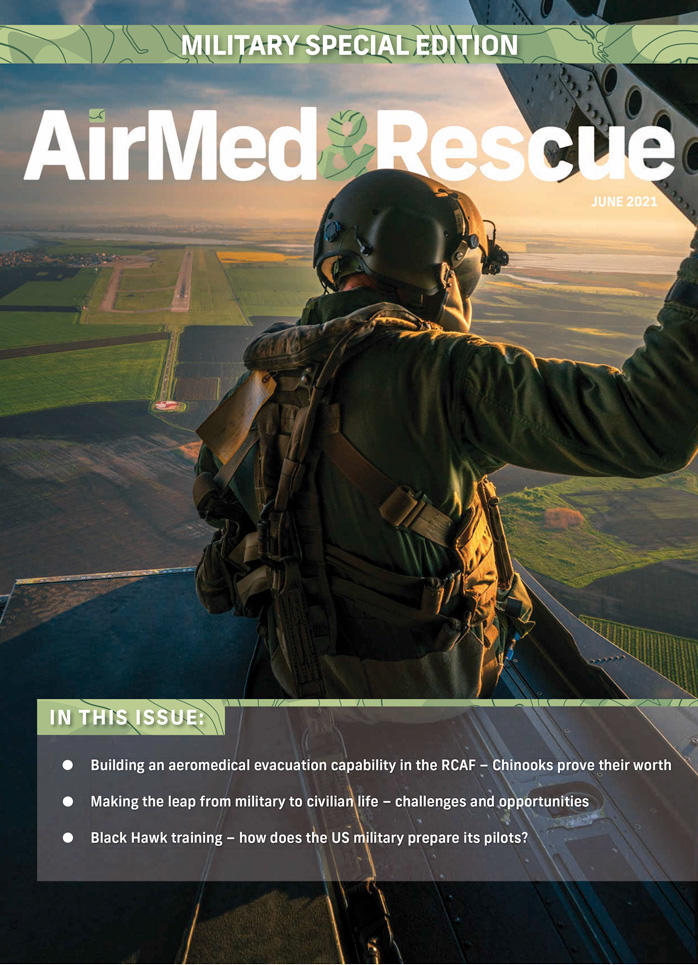

In this issue:

- Building an aeromedical evacuation capability in the RCAF – Chinooks prove their worth

- Making the leap from military to civilian life – challenges and opportunities

- Black Hawk training – how does the US military prepares its pilots?

- Giving old aircraft a new lease of life as aerial firefighters

- Interviews: US Air Force PJs past and present; Dr Neville Vlok, HALO Aviation

- Provider Profile: Keewatin Air

Editorial Team

The AirMed&Rescue Editorial Team works on the website to ensure timely and relevant news is online every day. With extensive experience and in-depth knowledge of the air medical and air rescue industries, the team is ready to respond to breaking industry news and investigate topics of interest to our readers.