Sustainability in engineering

Disruptive fuel and aircraft technologies are playing a key role in the aviation industry’s contributions to achieving global sustainability targets. Experts share with Lauren Haigh how they are approaching the challenge of incorporating sustainability into their materials and processes

In 2021, aviation accounted for more than two per cent of global energy-related CO2 emissions and the industry has both a role and responsibility in overcoming environmental challenges and assisting in the transition to net zero. Research and technology efforts in aviation are concentrated on reducing the global CO2 footprint of air transport by 2050 compared with 2005. The technological innovations helping to drive forward sustainability include developments to improve aircraft fuel efficiency and reduce their CO2 emissions. According to the International Air Transport Association (IATA)'s 2019 Aircraft Technology Roadmap report: “In the longer term towards 2050, radically new aircraft configurations will be required to reduce fuel burn and carbon intensity significantly.” As such, sustainability is being incorporated into aircraft design and engineering products and processes.

Rising to the challenge

A feeling of shared responsibility and the acknowledgement of an important commitment to environmental sustainability is felt among the stakeholders who shared their thoughts on the issue. “As a leader in the industry, we have a great responsibility to be good stewards of the world around us and that includes evolving our technologies to help tackle climate change, ensuring more sustainable practices are integrated in our overall company and putting ambitious environmental, social and governance (ESG) strategies into practice,” stated Scott McElvaine, Vice President, Business Development and Commercial Services, Pratt & Whitney Canada.

A critical part of this surrounds sustainable aviation fuel (SAF). According to the Federal Aviation Administration (FAA), SAFs produced from renewable and waste feedstock will be ‘critical to the aviation industry’s ability to meet the net-zero emissions goal and they have the potential to slash emissions by up to 100 per cent’. “SAF provides a ‘drop in’ solution to reduce lifecycle CO2 emissions for thousands of aircraft flying today and over the coming decades,” explained McElvaine. “The main challenge of SAF lies in rapidly scaling up production capacity, given that our current supplies are only able to serve less than 0.1 per cent of the world’s aviation fuel demand. At the same time, we need to develop sustainable feedstocks to support SAF, without impacting arable land for food production. Our engines are already ready to operate with SAF blended at up to 50 per cent with conventional Jet A kerosene, and we’re supporting efforts to make our engines ready for 100 per cent SAF blends in future.”

SAFs produced from renewable and waste feedstock will be critical to the aviation industry’s ability to meet the net-zero emissions goal

Bell is also is committed to sustainability and champions the importance of SAF in this regard. “We realised we must play a critical role in upholding our commitment to green operations, which is why in March 2021, Bell announced that it will begin incorporating SAF into all Bell Training Academy (BTA) and customer demonstration fleet aircraft,” affirmed Eric Sinusas, Director of Commercial Development Programs, Bell. “SAF provides a cleaner source of fuel to power rotorcraft and decreases the environmental impact of general aviation.” Sinusas said that in 2020, as part of Bell’s Achieve 2025 initiative, Textron established a new set of five-year sustainability goals. “These are to reduce greenhouse gas emission intensity by 20 per cent; energy use intensity by 10 per cent; water use intensity by 10 per cent; and waste generation intensity by 10 per cent,” he explained. “Bell is committed to supporting Textron and our customers with more sustainable practices, in order to support the aviation sector’s mission for a greener future.”

Innovation and improvement

Mark Burns, President of Gulfstream Aerospace Corporation, underlined the importance of innovation in upholding the shared commitment to sustainability: “The business aviation industry holds the leadership position in aviation overall towards reaching our goals for net-zero carbon emissions. Gulfstream has championed those efforts from the beginning and continues to do so through a laser-like focus on innovation,” he stated. “Whether it’s driving engine and aerodynamic design efficiency, reducing manufacturing waste or demonstrating the safety, reliability and utility of SAF, we are doing our part to help drive the industry toward a sustainable future.”

New materials are tested in accordance with our approved and certified internal stringent procedures and methodologies

Leonardo also told AirMed&Rescue about their approach to sustainability. “Continuous improvement is part of Leonardo’s DNA, and environmental sustainability is increasingly becoming an integral part of our design processes,” a spokesperson said. “Currently, different streams are active on new materials and processes within our engineering departments and laboratories with the goal to fully understand their performances, applicability and integration in such a demanding and regulatory driven environment as aviation. New materials are tested in accordance with our approved and certified internal stringent procedures and methodologies and with the support of our suppliers to gather all the necessary information. New manufacturing processes and their environmental impact are also assessed for integration along our value chain.”

Enhancing efficiencies

One important route to sustainability is improving fuel efficiency. Indeed, the sustainable Flight National Partnership sees NASA and the FAA working with industry to ‘accelerate the development of more efficient aircraft and engine technologies with a 30 per cent improvement in fuel savings’. McElvaine confirmed that one priority area for Pratt & Whitney Canada is continually improving the efficiency of engines to drive performance, fuel savings and emissions reduction: “The PW127XT engine is the new standard for sustainability for regional turboprop aircraft. It offers an additional three per cent fuel efficiency, as well as 40 per cent extended time on wing and 20 per cent lower maintenance costs compared with previous generations of aircraft, further extending turboprops’ inherent 40 per cent efficiency advantage compared with regional jets flying on equivalent routes.”

A second focus for Pratt & Whitney Canada is advancing hybrid-electric propulsion technology through an array of demonstrator projects. “These optimally combine fuel burning engines with electric motors and battery systems to improve fuel efficiency and reduce emissions,” explained McElvaine. “Our regional hybrid-electric flight demonstrator is targeting a 30 per cent improvement in fuel efficiency compared with today’s most advanced turboprop aircraft. In December 2022, we completed the demonstrator’s first engine run, and we expect flight testing to begin in 2024.”

New materials may bring several different benefits and advantages

It’s all material

New materials and manufacturing processes are an important part of the sustainability journey and yield additional benefits in terms of the development of increasingly lightweight components and leading to reduced fuel output. “New materials may bring several different benefits and advantages both to our customers and our operations,” confirmed Leonardo’s spokesperson. “Advanced materials and related manufacturing processes may lead to lighter components as the material is located exactly where it is needed to support the different load conditions. Lighter components means lighter helicopters and the less the helicopter weighs, the lower the fuel consumption.”

At Gulfstream, research and development (R&D) is an important element of the company’s sustainability strategy and this includes innovations in new materials. “We continuously pursue new innovations, materials and processes that will enhance the sustainability of our operations and our aircraft,” revealed Burns. “In terms of aircraft performance and engineering, much of that focus has been on enhancing the efficiency of the aircraft through advanced aerodynamics. The Gulfstream-designed wing and winglet introduced on the G650 greatly reduces drag, which makes the aircraft perform much more efficiently. We applied that wing design on the next-generation G500, G600, G700 and G800. Thanks to that continued focus on R&D, we innovated further on the more recently announced G700 and G800 with an all-new, high-speed winglet design on those aircraft, which enhances the speed capabilities of those aircraft and further increases efficiency.”

A burgeoning trend in aviation is the use of ceramic matrix composites

A burgeoning trend in aviation is the use of ceramic matrix composites (CMCs). Their ability to perform reliably at extreme temperatures and the weight savings are just two of their beneficial characteristics. McElvaine believes that further opportunities to improve efficiency and performance will result from investments in advanced materials, such as CMCs: “Pratt & Whitney recently opened its CMC Engineering and Development Center in Carlsbad, California. We are developing CMC-based engine core technologies in collaboration with NASA, as part of the HyTEC (Hybrid Thermally Efficient Core) program.”

A multifaceted approach

For Gulfstream, a key area of focus is on increasing sustainability of production operations through advanced manufacturing techniques: “The tools we have implemented in our next-generation production facilities reduce cycle times, decrease energy and water usage and eliminate significant waste,” said Burns. The company has already achieved impressive results: “We have reduced greenhouse gas emissions by 18 per cent while growing our capacity by 30 per cent,” he confirmed.

At Bell, multiple channels are being pursued simultaneously in a bid to achieve environmental sustainability, as Sinusas articulated: “Engineering design and innovation teams are pursuing alternate power sources, quieter flight, reduced operating costs and minimum environmental impact. Environmental health and safety teams and integrated operations are identifying opportunities to reduce factory energy utilization and minimize waste”. Such a multifaceted approach is key to overcoming a deeply complex challenge.

An attainable goal?

Indeed, this requires an intensive combination of collaboration involving diverse stakeholders and innovation across numerous channels and, of course, investment. “Achieving the goal of net-zero emissions for aviation will depend on our continued cross-industry collaboration as well as public–private partnerships to support the necessary investments in technology and infrastructure,” highlighted McElvaine. The Leonardo spokesperson agreed: “It is a challenging and demanding target, and Leonardo, being a part of the larger aviation sector, is actively working to support the transition to 2050 targets. Collaborations among industries, regulatory agencies, public bodies, institutions and operators is fundamental.”

Alongside industry collaboration, customer collaboration is necessary. “We are actively working with our customers and many other industry collaborators on a range of sustainable aviation initiatives to help accelerate efficiency measures, energy transition and innovation across the aviation sector,” said McElvaine. “For example, in November 2021, Pratt & Whitney Canada announced its participation in a long-term SAF pilot program with German air rescue operators, ADAC Luftrettung and their helicopter fleet. The collaboration will commit to operate SAF at blends of 30–40 per cent over the course of 36 months.”

The road to decarbonization shall be clearly defined and agreed through a strict and open collaboration

Leonardo’s customers are key collaborators too. “Customers flying Leonardo Helicopters’ products worldwide are active players along this journey to 2030 and 2050 and their active support in building together the future of this sector is crucial. The road to decarbonization shall be clearly defined and agreed through a strict and open collaboration with our customers to identify priorities required by the market and allow the industry to properly plan and deploy all the necessary resources and investments so as to match the market expectations.”

Burns emphasized the importance of taking responsibility and leading the way, with setting an example representing an important part of collaboration with customers. With aligned goals, progress will be forged: “We are fortunate that our customers want to partner with a company, like Gulfstream, whose sustainability goals align with theirs,” he stated. “It is up to Gulfstream, as the original equipment manufacturer, to offer sustainable innovations for our customers through SAF, aircraft design, efficiency and operations that help them achieve their own sustainability goals. By working together, we can make a larger overall impact.”

Innovations such as SAF and CMCs are creating waves in the industry

When it comes to forging ahead in the path to sustainability in aviation, innovation and collaboration are two key words. Innovations such as SAF and CMCs are creating waves in the industry and much of the R&D and advancements are beneficial not only to the environment but also to operators and their customers, leading to advanced models with increasingly desirable properties. In order to make headway, collaboration must be open and far-reaching, involving industry players and customers. In taking responsibility and leading the way, the experts who spoke with us are positively influencing the space. “We take this responsibility very seriously such that we can preserve and are prioritising every opportunity, innovative idea or new product to help our customers deliver cleaner, greener, and more sustainable air transportation, and enabling them to meet the industry’s net zero carbon emissions goal,” stated McElvaine.

Ultimately the aviation industry is an influential and crucial one and is embracing the opportunity to develop and implement novel aircraft technologies. With continued shared efforts and suitable financial tools and incentives, the industry is on an upward trajectory to a more sustainable future.

June 2023

Issue

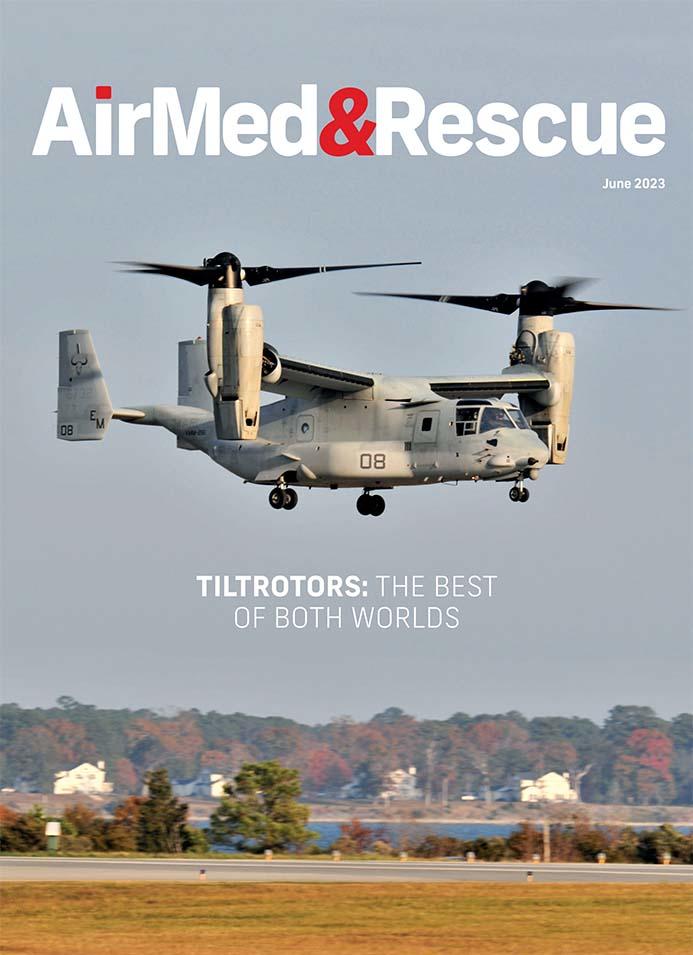

We find out about attracting the best staff; what is being done to improve sustainability; how tiltrotors compare with conventional aircraft; how rescue services approach sudden and extreme flooding; and the challenges facing MRO supply chains; plus all of our regular content.

Lauren Haigh

Lauren has worked in the publishing industry for eight years and reads and writes about healthcare, science and travel insurance on a daily basis. Her favourite aircraft is the plane from the title sequence of British educational children’s TV series Come Outside.