Stretchers and rescue baskets: Choosing the right product for the mission

SAR and HEMS organizations around the world make use of different stretchers and rescue baskets every day, so what sets apart the winning products? Mandy Langfield asks users for their opinions

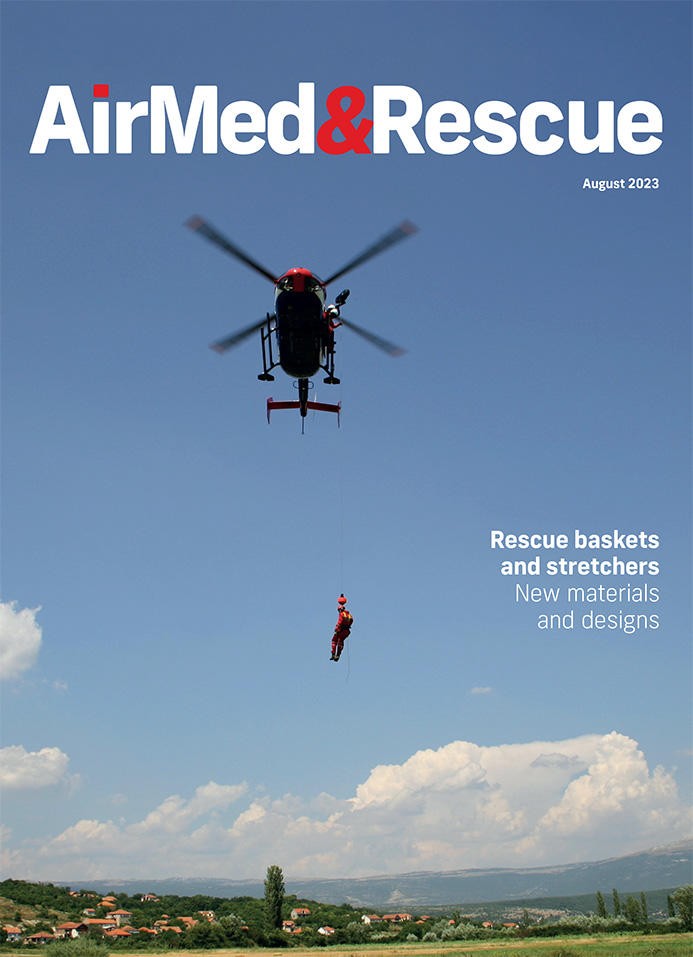

Black Wolf Helicopters operates in Central and South America, and the latest products available aren’t always the ones in use. However, changes in the materials and manufacturing processes that the makers utilize have improved the usability of the products, as well as the safety of them. “Nowadays,” said Chief Aircrewman Chris Sharpe, “bags, stretchers and baskets are more robust and lightweight, and ‘soft bags’ also include protection for the patient via a window for their face. Another advantage is that they are made of highly visible and reflective material, which aids dramatically in the helicopter/aircrew perspective of what is happening underneath the aircraft.”

Sharpe added: “We mostly use what is referred to historically as the ‘Bauman bag’, although the system we have now is the Air Rescue Systems ARES bag. I had the PEP bag from Priority 1 Air Rescue at my previous company.” He is clear in his opinion that ‘rigid stretchers should be consigned to the history books’. However, in Guatemala, where rigid backboards are used as the norm: “It also allows patient loading into the system without having to transfer them unless absolutely necessary, thereby saving time for the patient,” he said.

“Predominately,” Sharpe continued, “we chose [the ARES bag] for optimum patient care – safety, hypothermia protection, and the ability to use either a vacuum or orthopedic scoop stretcher. The main operational reason is that they take up little room and, unlike rigid stretchers, can remain folded for insertions through jungle canopies etc, without the risk of entanglement. This also enables them to be stored easier in the aircraft cabin due to their smaller packed sizes, and makes them more manageable by one rescue technician.”

Should the aircraft determine the stretcher?

More space in the larger, twin-engine helicopters provides scope for larger litters

The aircraft model will often have a part to play in helping the crews decide which stretcher or rescue basket they make use of. For example, more space in the larger, twin-engine helicopters provides scope for larger litters. New aircraft, furthermore, give operators the chance to work with product developers to customize their interiors and make the best use of space.

Air Ambulance Charity Kent Surrey Sussex (KSS) has the Model 1208 Translating Patient Loading System (TPLS) in combination with a Model 1555 patient litter, both manufactured by United Rotorcraft, installed in the fleet of three Leonardo AW169 aircraft.

As the UK helicopter emergency medical services AW169 launch customer, KSS designed the cabin interior in collaboration with United Rotorcraft and Specialist Aviation Services with patient and crew ergonomics at the forefront of the project. The size of the AW169 cabin provided the ability to have the stretcher mounted between the two forward-facing crew seats.

Richard de Coverly, Operational Delivery Director, KSS, said: “This provides almost 360-degree access to the patient and, with the accompanying medical bag storage system, allows medical equipment to be stowed and secured safely while remaining accessible to the medical crew in flight.”

The Model 1555 patient litter was modified to include low-friction rollers, while the Model 1208 TPLS was also modified to accommodate this interface.

“The new design of stretcher has made the loading and unloading process of patients easier and safer,” said de Coverly. “With wide sliding doors, the TPLS brings the stretcher out to a 90-degree angle at the cabin door, allowing side-by-side loading and unloading at a safe working height with clear reduction in the manual handling risks for both crew and ground support staff.”

When the stretcher is stowed in the cabin, the all-round access to the patient from both sides and the head end of the patient is allowing KSS to develop in-flight care processes, which has the potential to reduce the scene time for critically-ill and injured patients and enable more medical interventions to be delivered in flight while en route to hospital.

The new design of stretcher has made the loading and unloading process of patients easier and safer

Testimonials from across the operating spectrum

01 Rob Munday, Hoist Operator/Instructor at Blackcomb Helicopters and SR3 Rescue Concepts, shared his experience: “SR3 Rescue Concepts primarily uses and recommends the CMC Helitack AirBag. It’s affordable, functional, packs up small, and can be combined with most generic backboards and vacuum mattresses that local public safety agencies typically use. We have also had great success with the Cascade/Tyromont bags, and the Lifesaving Systems Corp basket stretchers, for a lot of the same reasons. Customer service is also key and these companies look after us exceptionally well.”

02 Adam Bancroft, Programme Leader in Healthcare Education, Bournemouth University: “Saviour stretchers – we have used and abused them in educational settings, and are worthy of your consideration.”

03 CHC Helicopter uses the 406-Titanium litters from Lifesaving Systems Corp for search and rescue in Ireland with the Irish Coast Guard, upgraded after more than a decade with the 404 steel variant. Gary Robertson, Technical Crew Manager at CHC Helicopter, commented: “[The 406] is super easy to handle and overengineered in every aspect for operating confidence. The float kits give a greater confidence lifting over water, and the customer support is simple, accessible and industry leading. Finally, the product lifespan is hard to whack.”

04 Dr Urs Pietsch MD, Air Zermatt, told AirMed&Rescue: “We use the PAX vacuum mattress and rescue bag for human external cargo operations.” The new rescue bag was developed as part of a cooperation agreement between MK-Med (Manfred Kinnast, former anesthetist and paramedic at Air Zermatt), PAX (Pax Professional Emergency Equipment, X-CEN-TEK Oldenburg), and the Air Zermatt medical service, specifically with the former head of the medical service, Axel Mann. “The last test flights for the new rescue bag took place in Zermatt in 2019. In 2021, the new bag was approved according to the Medical Device Directive. Since February 2022, it has also been approved according to Medical Direct Regulation, which is the highest level of approval.”

05 Dr Glenn McKay, Managing Director, Medical Rescue Group: “Through Aeromedical Engineering in Australia, we have focused on building lightweight composite stretchers for fixed- and rotary-wing aircraft that can be carried by our nursing staff from the hospitals back to the aircraft and on stronger loading ramps for fixed wing to cater for heavier loads, acknowledging that loading and unloading is a higher-risk period. For hoist / search and rescue work, it’s a basket and vacuum mattress.”

06 Dr Marjan Basmenji, MD, Flight Physician and Air Medical Examiner: “I have attended missions with different aircraft with different stretcher types and, from my point of view, Spectrum Aeromed stretchers are very ergonomic, safe and comfortable, both for patients and caregivers.”

07 Ian Bonthrone, Managing Director of Air Rescue UK,told AirMed&Rescue: “We use the Ferno Traverse titanium split basket stretcher, but our mainstay is the ARES stretcher.”

August 2023

Issue

We have a wonderful edition, covering aerial ECMO provision; hoisting and the lessons to be learned; the benefits of fixed-wing air ambulances; preparation for fire seasons; progress towards sustainable aviation fuel; and the variety rescue baskets; plus more of our regular content.

Mandy Langfield

Mandy Langfield is Director of Publishing for Voyageur Publishing & Events. She was Editor of AirMed&Rescue from December 2017 until April 2021. Her favourite helicopter is the Chinook, having grown up near an RAF training ground!