Pushing the envelope: flying in low-density air

Emergencies happen in hot and high environments. Rob Coppinger finds out how aircraft manufacturers are designing for these extreme situations

Helicopters and fixed-wing aircraft for medevac, ambulance flights and other special missions are being enhanced to ensure they can operate in the hot and high locations that make the job more perilous and where smooth and accurate flight can mean all the difference. As air gets hotter, at any altitude, it becomes less dense and stable, so flying through it is more difficult. Higher altitudes also present the same problem of thinning air, and at some elevations the temperature challenge is severe, with ice- and snow-covered terrain.

“Two of our customers that fly high and hot are Idaho Helicopters, out of Boise, Idaho, and they fly emergency medical services (EMS) missions with Air St Luke’s,” said Bell Helicopter Emergency Medical Services (HEMS) Segment Manager Steve Soliz. “They’ll go up into the mountains and they’ll fly up to 14,000ft. And they can get pretty hot.” Those companies have told Bell that in the summer the temperature can be as much as 100°F (38°C) on the ground.

“When you’re doing some of these high-altitude missions, such as helicopter EMS or search and rescue (SAR) and hoist operations, being able to stabilize the aircraft in the thinner air helps,” said Soliz. In Death Valley in California, where it is actually at sea level or below sea level, the temperature can get up to 140°F (60°C). In these high heats, taking off with the remaining fuel loads and also the weight of crew and patient can be hard work.

“Not being able to take off vertically as easily as you would in a normal environment is always a challenge when you have to do ... a running takeoff where you actually have to get the effects of effective transitional lift from the helicopter, to gain air speed and altitude,” Soliz explained. When temperature impacts helicopter flight performance, where a helicopter is to land and take off from needs to be a consideration. “You’re going to have to pick your landing zones and your rendezvous points based on the capabilities of your aircraft,” he added.

“If you’re rescuing somebody or recovering somebody from a higher altitude, a lot of times they may have some hypothermia issues,” said Soliz. “And so, warming them up and keeping them warm and keeping the cabin warm is an additional challenge too, within the aircraft, because it’s going to take a toll on your crew.” Working at hot and high altitudes can induce fatigue in a crew; it is “one of the things we’re always concerned about”.

Rotors, engines and visibility

When operating in hot and high conditions, for helicopter performance, rotor blade design is important, Stefano Pace, Leonardo Helicopters’ Head of Product Marketing for twin engines, explained. “[It’s a] very optimized design of the rotors in order to provide lift in any area of the [flight] envelope and also to provide the best in terms of comfort because we must remember that reduced level of vibration means also more comfort for the rear crew in the back and for the patients,” he said.

That reduced level of vibration means also more comfort for the rear crew in the back and for the patients

“Vibrations also have an impact on the stretcher, the body, the injuries that the body has sustained,” Pace added, “so the level of vibration, which is kept quite low, is important to provide the right level of assistance.”

Cabin design is important for weight considerations that can affect performance. Leonardo’s Marketing Specialist for law enforcement, SAR and the EMS market, Antonello Forcati, said: “We have a full range of rapidly reconfigurable cabins that helps in reducing the operational weight and getting more performance for the specific hot and high mission.”

Pace explained that hot and high was important for the engine selection on the AW189 model. “The certification of the AW189 was achieved with the General Electric engine and then, after a couple of years, we introduced the Safran engine – which is, by the way, the best combination for hot and high operations,” he said. “We introduced the Safran engine ... in order to operate really in the high-altitude conditions with an excess of power margin and useful load.” He also explained that, for the AW139, the most powerful engines in the class deliver an “excess of power margin in hot air and high conditions”.

In those hot and dusty environments where brownouts occur and at high elevations where snow causes whiteouts, Leonardo also offers an advanced system to increase pilots’ situational awareness. Pace said: “We have in particular the Synthetic Vision System, which provides 3D terrain depiction to avoid collision, enhancing pilots’ situational awareness also during the approaching phase.”

Takeoff performance

Textron Aviation’s Cessna and Beechcraft aircraft support a broad range of mission profiles, including air ambulance. For hot and high takeoff performance, the company provides an upgrade for its Beechcraft King Air 360C turboprop, which is a factory-installed, optional Pratt & Whitney PT6A-67A engine in lieu of the aircraft’s standard PT6A-60 engine. Textron states that the PT6A-67A offers higher thermodynamic limits, providing enhanced hot and high takeoff performance, faster climb to cruise altitudes and higher cruise speeds.

Digital automatic pressurization controllers have been added to these aircraft, allowing the cabin to be maintained at the lowest possible altitude to maximize the comfort of patients with head or chest trauma

For hot conditions, the Beechcraft King Air 360 has an electrically driven air conditioning system allowing for cooler air while the aircraft is on the ground, as well as in-flight. For air conditioning when not in-flight, it is plugged into a ground power unit. The cabin air pressure level can also be carefully managed on the King Air 260 and 360. Digital automatic pressurization controllers have been added to these aircraft, allowing the cabin to be maintained at the lowest possible altitude to maximize the comfort of patients with head or chest trauma. Most Cessna jets and Beechcraft turboprops are certified to operate at airfields up to 14,000ft without cockpit changes.

For the need to operate in wide-ranging environments, Textron points to its Cessna Citation Latitude business jet as an air ambulance aircraft. The Citation Latitude is operated as an air ambulance from the north of the Arctic Circle to the equator. This, the company states, is partly due to the performance range of the Latitude’s wing design. Textron states that the wing provides excellent short-field, high and hot performance.

Keeping weight, noise and costs down

United Rotorcraft produces the Firehawk, a multi-mission aircraft based on the Black Hawk whose missions include aerial firefighting. Another United Rotorcraft product is the HH-60 for medevac, SAR, cargo, transport and utility. “With the advancement in onboard medical equipment and the increasing average weight of patients, operators face a growing challenge balancing the equation of aircraft capability with the desired medical mission capabilities,” said United Rotorcraft. To address this concern, the company is improving its designs and upgrading its civil and military medical interior product lines to reduce weight.

The helicopters use rotor blades that are lighter, stronger, and smarter, which means we get more lift without working the engine into overtime, which is exactly what you need up there where the air is thin and hot

United Rotorcraft offers its customers interiors that can be reconfigured to meet specific medical requirements or remove unnecessary equipment to reduce weight. United Rotorcraft’s HEMS interior for Airbus H145 D3 or Bell 429 GlobalRanger allows customers to make such changes. Across United Rotorcraft’s cabin offerings, modular heating and cooling can also help battle those hot and high and cold conditions.

For that performance needed for hot and high and cold conditions, United Rotorcraft explained that its helicopters use rotor blades that are “lighter, stronger, and smarter, [which] means we get more lift without working the engine into overtime, which is exactly what you need up there where the air is thin and hot.” It added that its blades’ materials and designs help reduce operating costs. With civil use, the Federal Aviation Administration (FAA) is focused on noise pollution from both the engines and rotor wash decibel levels. United Rotorcraft stated that its blades technology makes its helicopters quieter with a reduced environmental impact.

For its engines, the company has included “technologies that help the engine breathe better and run cooler” in those extreme conditions. “Engines are absolutely key here,” said United Rotorcraft. “It’s not just about having the power but having it ‘smart’. Think advanced control systems like full authority digital engine control (FADEC) to make sure the engine is giving its best based on the altitude and temperature.”

Highest takeoff and landing

Airbus stated that its single-engine H125 helicopter has held the world record for the highest-altitude takeoff and landing – from Mount Everest, an altitude of 29,000ft – since 2005. In 2021, Airbus Helicopters gained certification for a performance increase of the H125 and this allows an increase of up to 140kg in hot and/or high environments for external payloads. The performance increase is an augmentation of the maximum usable engine power by its Arriel 2D engine. The engine power available is increased by about 10% compared with the baseline H125 model through a software update.

The Airbus twin-engine H145 has also shown it can operate at high elevations. The latest version has landed on the summit of the Aconcagua mountain, which rises to 22,840ft, in the Andes. “We had to stay focused on the mission due to severe winds with gusts up to 30kts and the low air density,” said Alexander Neuhaus, Experimental Test Pilot at Airbus Helicopters, in the company’s statement about the landing. “The handling qualities of the new H145 are excellent and, combined with Helionix and its four-axis autopilot, we reached the summit safely.”

This means improved performance in hot and high conditions with an additional gain of up to more than 2,300ft for its hover ceiling

The single-engine H125 model has been improved for hot and high conditions with the ‘FastFin’, where the main rotor airflow is used to increase the effectiveness of the helicopter’s anti-torque system. According to Airbus, this means improved performance in hot and high conditions with an additional gain of up to more than 2,300ft for its hover ceiling. Another way to increase hot and high performance is to decrease a helicopter’s weight. Airbus Helicopters reduced the official empty weight of its H160 medium utility model and the firm states that with the related reduced fuel consumption of about 3%, the H160’s payload capacity increases by about 100kg.

Maximum agility

A well-known military aircraft used for SAR and medevac is the Boeing Chinook. “We continually upgrade our enduring fleets to be more capable for all missions and conditions they operate in,” said Boeing Vice President and Cargo Helicopter Program Manager Heather McBryan. “For example, with our Chinook Block II program, we have upgraded the airframe, the drive and rotor system, and avionics to be more resilient in a variety of conditions, including hot and high altitude.

“All those technologies help deal with the less dense air that helicopter platforms encounter in hot-and-high-altitude environments. Additionally, the tandem-rotor design provides for increased stability and control, maximum agility, and allows the Chinook to fly at up to 20,000ft, much higher than any other heavy-lift helicopter on the market.”

Whatever the market, civil or military, whether it is medevac or SAR, the propensity for people to operate in hot and high settings means the emergency services operator has to be able to access those locations. The need for aircraft improvement for those challenging environments will continue to be driven by these market demands.

August 2024

Issue

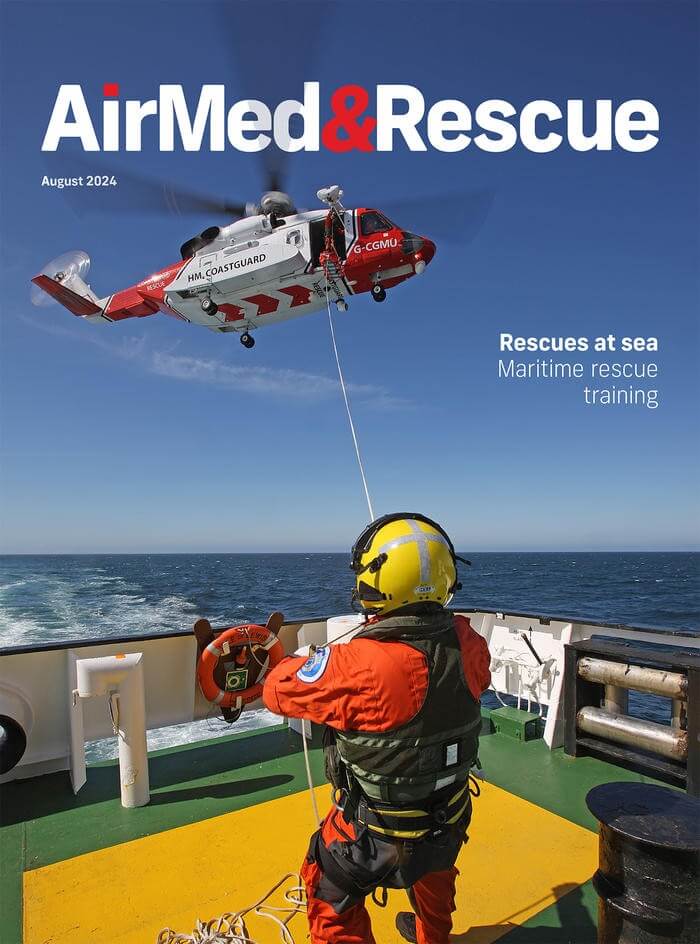

In our August edition, find out about pilot and hoist operator training for maritime missions; learn about the way that rescue swimmers get trained; discover what goes into making an aircraft fly in hot and high conditions; read about the development of mechanical ventilation for air transport of patients with respiratory conditions; and see what goes into the execution of aerial firefighting across Canada; plus more of our regular content.

Rob Coppinger

Rob Coppinger is a veteran aerospace writer whose work has appeared in Flight International, on the BBC, in The Engineer, Live Science, the Aviation Week Network and other publications. He has covered a wide range of subjects from aviation and aerospace technology to space exploration, information technology and engineering. In September 2021, Rob became the editor of SpaceFlight Magazine, a publication by the British Interplanetary Society. He is based in France.