Master of his craft

Mandy Langfield spoke to Jarrett Lunn, Chief Pilot for Talon Helicopters in Canada, about flight crew currency, safety and regulatory advancements in the rotorcraft industry

What is your background in the rotorcraft industry, and what first drew you to it?

I started my career flying on the North Coast of British Columbia with a few years of ground crew duties, driving fuel trailers, washing aircraft and whatever else I could do to help and learn from the experienced pilots and engineers. I slowly picked up flight hours, and by the end of my third year in the industry, had enough experience to fly full-time. Since then, I have done a variety of work – firefighting, heliskiing, medevac, VIP, exploration camps in the Arctic … but have always enjoyed external load operations the most. Whether it is a precision lift job in the middle of the city or hoist rescue off a mountaintop, that is the flying that gets me most excited!

What helicopter types do you fly, and how frequently has this changed over the years? Do you prefer one aircraft over another?

I currently fly all Airbus helicopters: the AS350, AS355 and AS365. Over the past several years, most of my operational hours are on the AS365, which is my favorite! Being a Cat-A, twin-engine aircraft, which we fully rebuild with amazing avionics and night vision systems, it’s a hard one to beat. The other great thing about that aircraft is the work we get to do. Hoist rescue and firefighting, both by day and night using night vision goggles (NVGs), with a great utility machine. We have been able to do some pretty neat lift jobs over the years.

Is it a challenge to maintain currency on different aircraft? Do you use a simulator for training or are you always able to fly the actual aircraft?

With three helicopter types, all from the same manufacturer, it is not too difficult to maintain currency on them. The logic behind how the electrical systems are laid out, the hydraulic setups, the startup / shut down procedures – they all pull off of the same framework. Now, as the machines get bigger, they get more complex (single hydraulics in the AS350, dual hydraulics in the AS355 and four hydraulic systems in the AS365), but the knowledge is easily transferable from one to the next. I don’t think this is as smooth if you fly three helicopters from three different manufacturers. I have taken simulator courses and they have great capabilities, but we do all of our training on the aircraft at Talon.

How have modern avionics changed how you fly the aircraft? Does cockpit automation save lives?

We fly a mix of traditional steam gauges and more modern GPS and avionics, so I cannot speak directly to full glass cockpits. One thing on automation is the need to really understand the system as a pilot. When you’re first introduced to a fully coupled autopilot and modern instrument[1]flight-rated GPS (we have a three-axis autopilot and Garmin GTN750 in the AS365), it can feel intimidating to use these features – and the pilot will tend to just hand fly, as if those automation functions aren’t even available. But if the systems can be learned and their features and limitations fully understood, they can drastically reduce pilot workload and lead to a much safer operation, especially in marginal conditions or high workload environments.

For me, the biggest change I have seen is a longer and less predictable fire season. We were bucketing well into October in 2022!

You’ve been with Talon Helicopters for almost 10 years; how have you seen the industry change in that time in Canada, whether in terms of the competition, quality or another way?

Wow, 10 years … time flies when you are having fun! For me, the biggest change I have seen is a longer and less predictable fire season. We were bucketing well into October in 2022!

Many industries have reported challenges around recruitment and talent retention. What is your experience? Are there more jobs than pilots?

We are fortunate to have a very low turnover rate compared with other operators in our industry. When hiring, we have always been able to find crew to fill our required roster spots, but there are less-qualified pilots applying than what we saw five to 10 years ago. I do think there is a shortage of qualified pilots.

Night vision imaging system regulations can stifle SAR and nighttime firefighting efforts. What has changed for Talon lately that has enabled more efficient use of resources at night?

For Talon, our regulatory approvals with Transport Canada all went very smoothly for our NVG operations. Where we had more difficulty was convincing certain clientele, who had no NVG experience, that flying at night was safe. People tend to stay away from things they don’t know or don’t understand. It makes them feel like they are being risk averse by just saying no to night ops, but in reality, we are implementing this tool to reduce risk, not increase it. One example is removing the pressure to ‘get the job done’ before dark on a SAR mission. Using NVGs, we can continue to operate at our standard pace, whether we are two hours, or two minutes from dark. This is a safety benefit for the pilot, who now doesn’t have the pressure to rush the job. Also, it’s a safety benefit for the SAR crew, as they won’t have to hunker down on the side of the mountain and wait until sunrise for their hoist out with a potentially dying subject.

Using NVGs, we can continue to operate at our standard pace, whether we are two hours, or two minutes from dark. This is a safety benefit for the pilot, who now doesn’t have the pressure to rush the job

Being able to customize aircraft for the various missions you undertake – fire, HEMS, utility, movies – is key. What are the most frequently used pieces of equipment for fire and HEMS missions, and how much does flexibility and ease of addition/removal of the kit matter when choosing which equipment to buy?

Our helicopters really are multirole, so mission equipment is critical. For fire operations, we will frequently switch from longline and bucket to belly tank operations, depending on terrain, proximity to built-up areas and day versus night operations. For HEMS, we are primarily a SAR aircraft so we run as light and clean a cabin as possible, to keep weight down and clutter to a minimum for doors-open searching or hoist ops. We also help out with the provincial ambulance service when they need an extra aircraft. That is a separate setup, with more fixed equipment such as a roll-on/roll-off stretcher and oxygen tanks. We need all of these setups to pop in and out in a hurry, as we pride ourselves on being able to launch with little notice to assist any of our clients in need. If we cannot commercially source a product that works for us exactly how we want it, we will put in the work and develop our own STC, which we have done several times.

Safety in helicopter operations is always a key focus for operators; what SMS do you engage in/use, and how has this developed and changed as time goes on?

We have been running an SMS system for quite a few years – and the biggest change over time is simplification. Complex charts, graphs and spreadsheets with risk matrixes may look nice, but in our experience, they don’t tend to help anyone. We have simplified our SMS down to the basics, ensuring our operational and safety requirements are met, and that any improvement ideas or concerns by our staff or clients are reviewed and shared throughout the team. The system is not perfect and may never be, but we keep working on adapting our SMS to work for our needs.

What are you most looking forward to in 2023 in terms of industry development or company progression?

Continuing what we have going, having fun in the air, while hopefully getting to try out some new stuff too!

January 2023

Issue

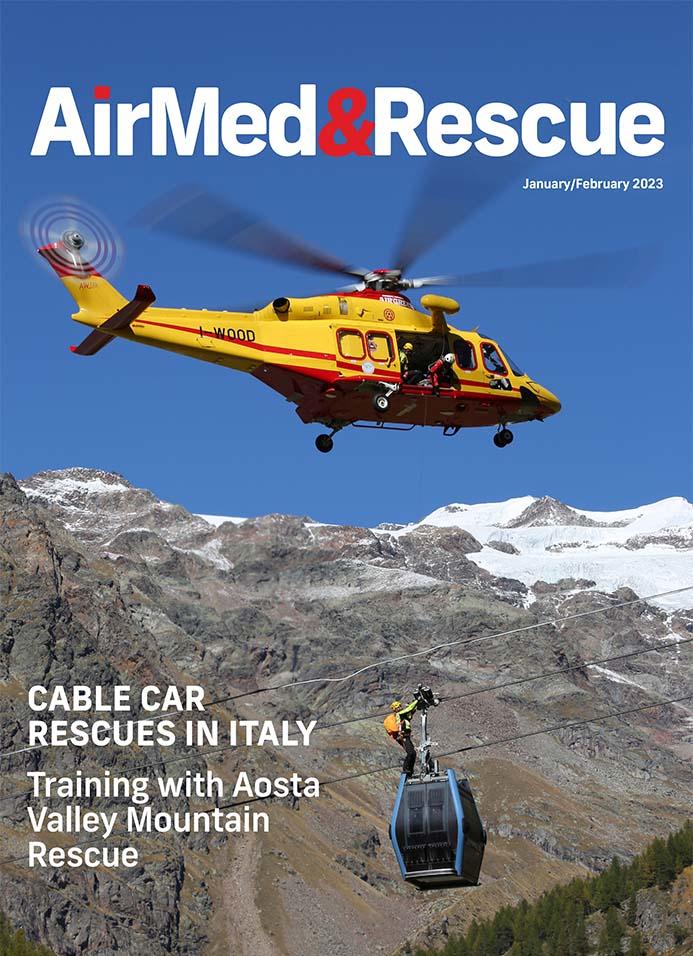

In the January/February 2023 issue

Technology to aid, enhance and support you in the cockpit; how do HEMS operators around the world approach SAR with different rules and technology; what do people know about AA: who can access it, when can they use it, how much does it cost, and how is it funded; plus a whole lot more to keep you informed and good to go!

Mandy Langfield

Mandy Langfield is Director of Publishing for Voyageur Publishing & Events. She was Editor of AirMed&Rescue from December 2017 until April 2021. Her favourite helicopter is the Chinook, having grown up near an RAF training ground!