Kissing the Helitak way

Nicholas Noorman, Business Development Manager, Jordan McKenzie, Production Coordinator, and Harry Bailey, Production Manager at Helitak explain why their simple approach makes Helitak stand out

Helitak Firefighting Equipment builds tanks ranging from 1,000-11,000L. How does it manage this with only minimal modifications to aircraft airframes?

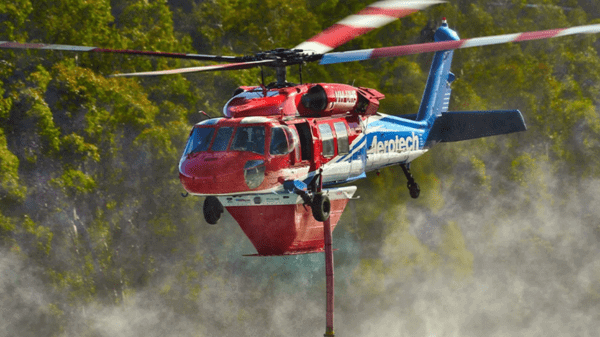

We build our tanks so that they integrate to aircraft using the existing original equipment manufacturer (OEM) hard points. In probably 95% of cases, we’re using existing aircraft hard points, and through clever design we’ll very rarely have to add any additional hard points for affixing our tanks. A lot of our systems are rather simple, like on the UH-60, which just has a couple of stabilizer arms, the hook carries 74% of the load and the front External Stores Support System mounts carry 26% of the load. The result is no expensive airframe modification required to install the Helitak tank. With minimal cost for the aircraft and for the operator. Each of our tank installations is designed around each unique airframe.

There are many new platforms entering the market/industry, including uncrewed aerial vehicles (UAV). How does Helitak adapt to the new platforms?

We get approached by aircraft operators who might already have existing aircraft and we will adapt to their needs. If an aircraft’s already in the market it’s quite easy because that that data is out there.

With computer-aided design (CAD) and 3D modelling, we can then make sure that it’s all going to work, and that it’s all going to fit. We always ensure that our designs don’t exceed any of the airframe limitations set by the OEM. We also utilize 3D printing in our designs and our prototyping, so we can validate that everything’s going to fit and be functional before we actually start getting components machined.

We also get approached by OEMs and they’ll provide that data on new platforms. When we start with a new design, we say “Show us where your hard points are” and “Tell us what your lifting capacity is”, then we’ll design the tank to suit the aircraft. The thing with Helitak is that we try and keep our tanks as light as possible within limits. We start to meet all the load testing requirements of the structure, we try and keep the weight of our tanks to the minimum to maximize the available weight that aircraft can carry.

The Hover pump is designed to draw water away from the bottom of the water source, preventing ingestion of rocks and debris. How else does Helitak approach design to improve the service and longevity of its products?

We really do follow the KISS approach – Keep It Simple, Stupid. There’s no need to reinvent the wheel. It’s round, and it works. So we really do try and keep things as simple and as functional as possible. And repetitive. That’s the other thing; there’s no point designing one-offs every single time. Probably 85% of the components on our tanks are used across all our tank models. So we keep our door design and our ram design, and we use the same fire tank control system across all our platforms and our buckets – we’re using the same systems. This allows us to try and minimize the part count. We try and minimize the amount of moving parts within our tanks to improve the functionality and durability of the product.

What other new products or designs is Helitak releasing to aid aerial firefighting operators?

The buckets are a new product that we are releasing. We’ll manufacture buckets from 800L (210gal) up to our 10,000L (2,641gal) range. You could say that this comes from a request from our customers to provide that product line; many customers have asked us to build them and we’re just following what they want. Helitak is recognized as a tank manufacturer, but we understand that every one of our customers is also a bucket customer. Both play an important role and there are very different applications as to where one platform is better than the other. The main one that comes to mind is that a bucket can’t be used over an urban environment; when you’re fighting fires over populous areas of people or structures, that’s where tanks come into their own. On the other hand, if you’re fighting a mountain fire where you’re in deep ravines, and the water source is in the bottom of a gully, then a bucket on a long line is better suited for this environment.

Operators who have both tanks and buckets can quickly change between what platform is best suited to the environment. With our tanks and buckets, they can interchange between them using the same flight control system. The pilots’ muscle memory is the same across both platforms, they just have to switch from tank mode to bucket mode using our same interface inside the cockpit. It’s easier, safer and cheaper than having multiple systems across multiple platforms.

April 2024

Issue

In the April special aerial firefighting edition, learn about the techniques and tools being employed; find out about the diverse capabilities of uncrewed aerial vehicles; see how the European Union is consolidating resources; review the damage that Australia has suffered from bushfires; explore Indonesian search and rescue processes; and consider if your helmet is due for a service or replacement; plus more of our regular content.

Editorial Team

The AirMed&Rescue Editorial Team works on the website to ensure timely and relevant news is online every day. With extensive experience and in-depth knowledge of the air medical and air rescue industries, the team is ready to respond to breaking industry news and investigate topics of interest to our readers.