Industry Voice: The Breeze-Eastern Four-Strand cable

Innovation is at the core of Breeze-Eastern’s Four-Strand cable. Immune to looseness and with superior performance, the Four-Strand cable is the next-generation cable for hoisting

For over 80 years, Breeze-Eastern has designed and manufactured battle-proven aerial rescue equipment, including rescue hoists, winches and cargo hooks. Each product is carefully crafted to support demanding mission scenarios and safety, ensuring the job gets done efficiently and with the best tools available. Using a wire rope cable, hoists raise and lower personnel or other cargo from an airborne helicopter. With today’s missions requiring faster hoisting and longer wire rope cables, a reliable and safe cable is essential – this supported Breeze-Eastern’s development of an alternative solution explicitly designed for helicopter rescue hoists.

The next-generation Four-Strand cable is certified and patented – serving as a form, fit and functional replacement for the industry standard 3/16-inch diameter MIL-DTL-83140, 19x7 construction cables. Years of laboratory and flight testing supported by the United States Army have demonstrated superior performance capabilities, improved resilience and lower lifecycle costs compared with the legacy cable. The legacy cable consists of 19 strands, with seven wires in each strand, configured with an inner core of seven and an outer sheath of 12 strands. This design lends itself to a phenomenon called cable ‘looseness’ or ‘milk-down’, where strands permanently shift from the required position. Cable looseness is a common problem in hoist operations today.

The Four-Strand uses modern technology to interlock the four strands throughout the entire length of the cable. With no inner core, this next-generation cable is not susceptible to cable looseness. The revolutionary design is highly resistant to abrasion and features improved rebound margin and shock load capacity. The Four-Strand also boasts a breaking strength superior to military specification 19x7 cables and exhibits excellent fatigue characteristics. Some reviews from current users of the new cable state that, operationally, there is no difference for the pilot. The cable also allows crew members to focus more on training and less on cable issues and cable replacement. One hoist operator reported replacing 43 legacy cables in a year due to looseness considerations; however, since transitioning to the Four-Strand in 2018, there have been no reported cable replacements. From a maintenance perspective, the Four-Strand features upgraded reliability and product life, decreasing overall cost and downtime, while improving mission readiness.

The Four-Strand has earned multiple civil and military airworthiness certifications and is currently operating on several aircraft platforms worldwide. The improved reliability and safety of the next-generation Four-Strand cable will lead to reduced life cycle costs, improved crew readiness, and increased confidence in the rescue hoist mission.

August 2023

Issue

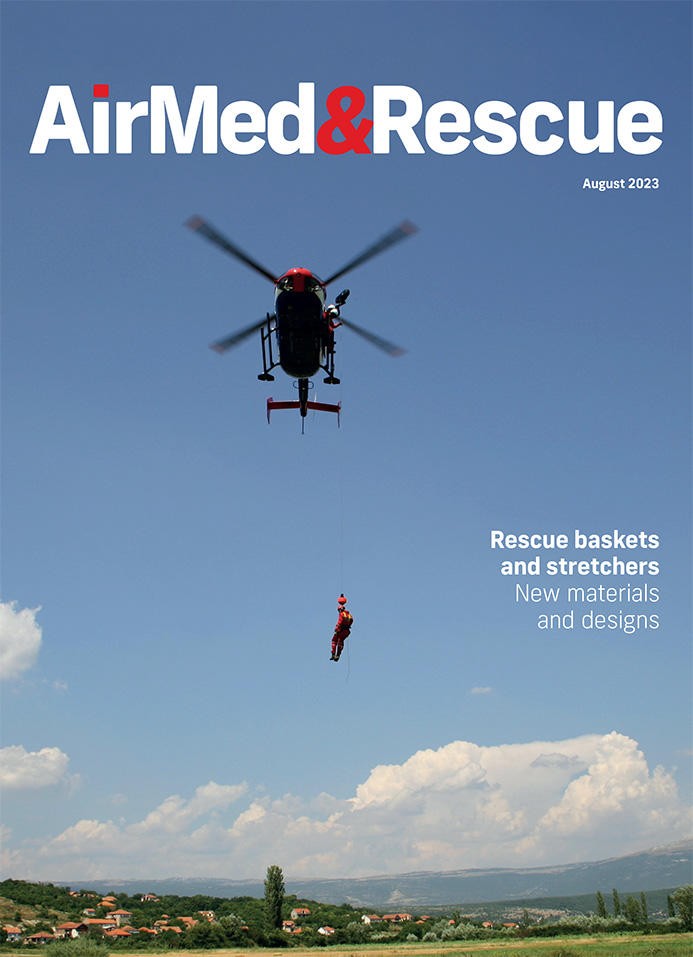

We have a wonderful edition, covering aerial ECMO provision; hoisting and the lessons to be learned; the benefits of fixed-wing air ambulances; preparation for fire seasons; progress towards sustainable aviation fuel; and the variety rescue baskets; plus more of our regular content.